Solutions

Cotton Gins, Ginning Systems, Delinting Bags & Replacement Parts

PROBLEM: Efficiently separate seeds from lint in smaller quantities required for cotton breeding and development programs in R&D labs, limited production run environments and field applications. Large ginning systems set up for high-volume runs do not typically provide the versatility required for these smaller run applications.

SOLUTION: Compass Micro(MG) & Table-Top(TT) Gin Machines and Ginning Systems were developed to provide the short-run flexibility required for cotton breeding and development programs in Research and Development and limited production applications. These machines efficiently and reliably separate cotton seeds from lint with the lowest tested VMD (Visual Mechanical Damage) on the market.

The Compass Gins and Ginning Systems are designed to exceed all other gins and ginning systems as to safety, quality, standards, ergonomics and production. The Compass Gin Ribs are especially designed for ginning a soft seed roll and to restrain smaller seed from flowing out with trash or fiber. Air and Fiber flow within the Compass Gins is smooth with the passageways and ducts designed to avoid tags and dead-areas where fiber, seed or trash could become lodged. For operator safety, Brake Motors, Machine Guarding and Safety Interlocks are integrated into all of our Gin designs.

Through customer requests, Compass has also designed and fabricated Long-Life Delinting Bags for your fuzzy seed acid-delinting applications. The bag material, thread and zipper components are all designed and fabricated out of acid resistant materials and the bag surface is also designed and been proven to mitigate the effect on the shell of the seeds. Bag life has been proven to be 50X other delinting bag materials and offered in a variety of sizes to fit your application.

Overview:

Micro & Table-Top Gin Machines

- Lowest tested VMD (Visual Mechanical Damage) for better seed yields

- Single piece "rib plate" design to more accurately manage saw - rib clearance

- See through side panels to visually confirm no fiber and seed contamination

- Available in global electrical standards

- Designed to meet stringent safety standards

- Replaceable wear parts available

- FULL LINE OF REPLACEMENT PARTS AVAILABLE (Regardless of Brand) - Contact us for more info and in stock items.

Compass GINS are available in two standard sizes:

- MICROGIN(MG) 10-Saw Gin Machines: These fixed location machines can be used in stand alone applications or as part of a custom-designed Compass ginning system. When used as part of a system, cotton bolls can automatically be fed into the machine with the separated cotton lint pneumatically conveyed away while seeds are recovered. This model (MG1010) is available in a number of electrical, lint collection and dust collection options.

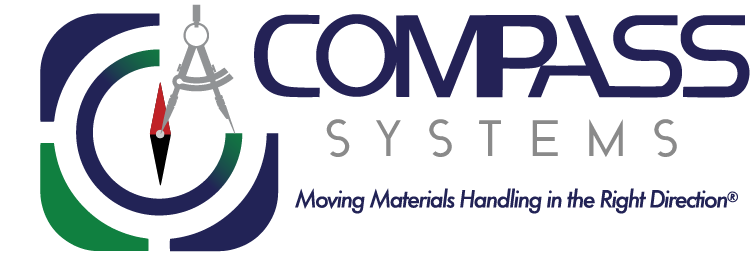

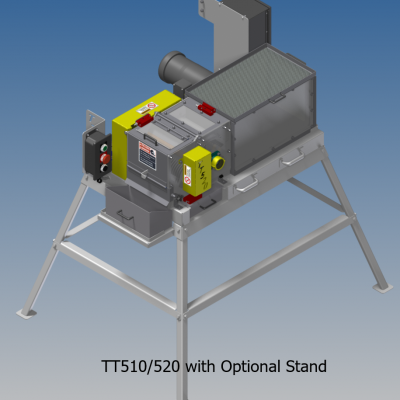

- TABLE-TOP(TT) 10-Saw or 20-Saw Gin Machines: These smaller, exceptionally versatile machines can be used as table-top lab equipment or easily put on a truck to use in the field. They provide fast, on-the-spot separation of seeds from lint for testing applications and have large seed containers. These machines are available in both 10-saw (TT510) and 20-saw (TT520) models and in a number of electrical, lint collection and dust collection options.

Compass Provides Complete Turnkey Solutions

Design / Controls / Procurement / Fabrication / Installation / Startup

MG1010 Gin Unit

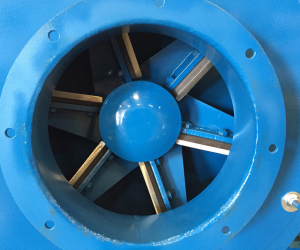

Material Handling Fan

Pneumatic Conveyor Duct System

Compass Guarantee:

We will guarantee that our dust collection systems will perform as promised to improve the health, safety and cleanliness of your plant. The complete Compass Systems Guarantee is available here.

System Audits:

Please reach out to our technical team regarding a system audit, and potential Compass-engineered solution to ensure your material handling system is maximizing productivity and return on investment.

Similar Solutions

CS&S provided the pneumatic conveying systems solutions for: