Industries

Material Handling Solutions for Automotive Stamping

Types of Automotive Systems

- Front of Line Conveyor Systems

The first step in handling metal scrap is getting the material into the queue for processing. The front of line conveyor system is the first step in that process. This step also includes washing and lubrication. - End of Line Systems

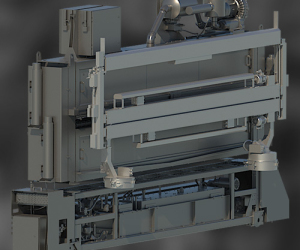

Compass End of Line Material Handling Solutions Integrate Conveyors, Automation, Robotics, Inspection and Packout Tables to provide improved productivity through increased uptime, improved operator ergonomics and best-in-class production rates. - Automotive Body and Blanking Sheet Scrap Segregation Systems

Compass Scrap Handling Systems are designed to maximize our customers’ uptime and scrap profits by offering a range of solutions from single to multiple stream segregation for optimal purity multiple stream segregation scrap handling solutions.

Compass has developed All (En)Compassing solutions

For automotive companies and suppliers worldwide:

OVERVIEW:

COMPASS AUTOMOTIVE INDUSTRY EXPERIENCE

- Compass systems use the least number of moving parts.

- Robust systems handle tough metals, maintaining uptime and reliability.

- Sophisticated controls provide reliable visibility and automated maintenance.

- Top quality component fabrication ensures reliable performance

- All (En) Compassing Solutions Provide Single Point Accountability

Related Case Studies

DESIGN & ENGINEER

We have pioneered ways to move different grades of metals with the least amount of moving parts. This makes Compass systems less prone to failure, downtime and costly maintenance requirements. Our automated conveyance systems use integrated control systems to reduce labor costs sophisticated controls also monitor and maintain process visibility in challenging environments and facilities operating 24/7. We use all major sensor brands and match them to the application to ensure both system reliability and dependable monitoring.

In recycling operations, we used tough shredders to maximize the amount of material deposited into rail cars or trucks. The pneumatic system used to transport materials to the shredders are equally tough, often requiring coating of inner tube surfaces to combat abrasion. Our recycling systems have provided 99% reliable material segregation resulting in higher scrap values and elimination of secondary processing.

Fabrication

We fabricate components for material handling systems in our Ohio factory. Here our ASME certified welders ensure that fabrication of components meets or exceeds customer requirements. Every part of a custom system is fit together and tested to ensure smooth installation and reliable performance.

Installation

Once your system is fabricated and shipped to the job site, we’ll be there to install it. We have supervised and built material handling facilities worldwide.

Service & Parts

We are always by your side, with global service support on all of our systems and other systems you may need support with. Call us for service support, on site audits or other needs our service department may be able to assist with.

CS&S provided the pneumatic conveying systems solutions for: