Solutions

Dust Collection

PROBLEM: Dust generated by manufacturing processes, or material conveyance can cause severe problems for employee health, product quality and even plant safety. Getting dust out of the manufacturing environment, without compromising airflow balance, can be a complex problem.

SOLUTION: Compass is one of the most knowledgeable resources for wet and dry dust collection systems of every type and size. Our engineers always start by looking at the entire production and conveyance system to understand the nature and extent of the dust problem. The best solution is usually the most comprehensive, incorporating efficient dust removal and filtration while maintaining sufficient air flow balance throughout the plant. The goal is always to make the interior manufacturing environment healthy, safe and clean while delivering the best possible life cycle value. Compass solutions are compliant with NFPA Guidelines and meet OSHA and EPA requirements.

We incorporate dust solutions into our pneumatic material conveyance solutions as needed and also engineer, fabricate and install dust collection for systems designed for others. Every one of our dust collection systems is set up to do at least one of three things:

- Alleviate health risks caused by high concentrations of dust in factory air.

- Improve product quality where dust on finished products impairs quality.

- Improve plant safety by eliminating and safely handling potentially explosive dust.

With one of the most experienced engineering staffs in the dust control industry, we are well aware of how complex a good dust collection solution can be. Determining the type and volume of dust in the air is an important first step. The smaller the dust particles and the higher their concentration per cubic foot of air, the greater the fears of combustibility. We have also developed solutions that turn some types of dust into recyclable briquettes.

The most basic dust collection solutions start with pick-up where dust is created. Innovative Compass Slitter Dust Vacuum Systems pick up dust at the actual generation point in paper slicing operations.

Dust-laden air is then conveyed using vacuum power to a cyclone hopper where dust particles are captured in filters that use auto-pulse cleaning to shake dust into collection units. Clean air is either discharged from the building or recycled to maintain heat and suitable air flow inside the plant. Sometimes outside air has to be brought into the plant to maintain air flow balance.

We work with a wide range of dust collectors, optimizing and fitting the appropriate dust collector technology to the application. These technologies include: Reverse Air Tube Type Collectors, Vertical and Horizontal Collectors, Pulse Jet Tube Type Collectors, Cartridge Type Collectors, Wet Separators, and Wet Scrubbers.

In some applications, particularly in the paper industry, wet systems use vacuums to draw dust-laden air into RotoClone dust collectors where particulate is sprayed down with fresh or white water. If there is a particularly high volume of dust being collected, we may need to put pre-separation equipment in front of the dust collectors.

Over the years we have also developed a special expertise in briquetting systems that use pressure to turn dust into recyclable briquettes. In some applications we have eliminated expensive landfill payments while creating profitable briquette sales to recyclers.

Material Handling System with Dust Collection

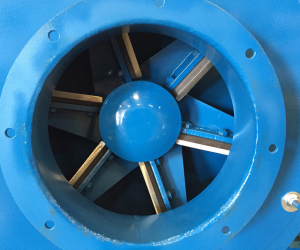

Material Handling Fan

Dust Collector Unit

Material and Air Separator With Conveying Air Removal

Dust Collection with Briquetting System

Dust Collector Unit Mounted on Custom Engineered, Stand Alone, Building

Screw Conveyors

Briquetter Unit

Multi Line Material Handling System

Material Handling Fans

Dust Collection with HEPA Filtration

Material and Air Receiver with Dust Collection Shroud

Air Handling Fan Unit With Discharge Diverter

Inline Silencer Unit

Laser Dust Collection System

Dust Collector Unit

Air Handling Fans with Custom Designed Sound Enclosure

Briquetter Unit

Clean Air Discharge Diffuser Duct

Dust Collection System For Laser Cutting Operations

Multi-inlet Manifold Pneumatic Conveying System for Dust Particles Generated by High Speed Laser Cutting Operations

OVERVIEW:

Compass Dust Collection Systems

- Every Compass dust collection system accounts for the needs of the entire production and conveyance system.

- Complex dust collection systems are engineered to minimize Life Cycle Costs.

- Particular attention is paid to balanced airflow throughout plant.

- We are industry leaders in both dry and wet dust collection systems.

- Roto-Clone® units use white water to provide high-speed separation of dust from conveyed materials.

- Specialists in engineering low-noise dust collection systems.

- Systems designed to pick up and convey dust created by any process.

- Slitter Dust Vacuum System picks up dust at the point of generation from paper-slitting operations.

- Briquetting systems eliminate combustibility while converting dust to a recyclable product with resale value.

DUST COLLECTOR TECHNOLOGIES

- Reverse Air Tube Type

- Vertical and Horizontal

- Pulse Jet Tube Type

- Cartridge Type

- Wet Separators

- Wet Scrubbers

- Roto-Clone®

Compass Guarantee:

We will guarantee that our dust collection systems will perform as promised to improve the health, safety and cleanliness of your plant. The complete Compass Systems Guarantee is available here.

System Audits:

Please reach out to our technical team regarding a system audit, and potential Compass-engineered solution to ensure your material handling system is maximizing productivity and return on investment

Similar Solutions

CS&S provided the pneumatic conveying systems solutions for: