Industries

Film / Foil / Laminates

Important Considerations

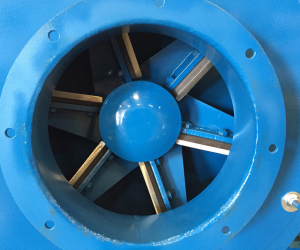

The combination of our experience in paper and metal scrap recovery systems led to development of some exceptional solutions for the recovery of film, foil and laminate scrap. Since these materials are tough on fan blades, we most often use Venturi or Negative Vacuum Systems to recover, convey and collect scrap generated during production. We have systems in operation today handling everything from ribbon to matrix configured scrap.

Many of these materials are coated and can be sticky. In these cases, our experience with plasma-coated conveyance tubing is helpful. These coatings prevent material bunching at key points in the conveyance system and causing blockages. Our custom-engineered systems deliver scrap to any collection point, including balers perfectly sized to the application.

When handling scrap from film, foils and laminates, our experience with dust recovery systems often plays an important role. This includes solutions to recover slitter dust at the nip point and centralized dust recovery systems to ensure dust from cutting operations does not cause safety, health or maintenance problems in the plant.

Overview

Compass Film / Foil / Laminates Experience

- Compass systems use the least number of moving parts.

- Experience with Venturi and negative vacuum Systems creates solutions where abrasive and sticky scrap does not come in contact with fan blades.

- Compass systems handle everything from ribbon to matrix-configured scrap.

- Plasma coated conveyance tubing prevents sticky scrap from impeding airflow.

- Sophisticated controls provide reliable visibility and automated maintenance.

- Custom-engineered dust recovery systems can be added as required.

- All (En) Compassing Solutions Provide Single Point Accountability

DESIGN & ENGINEER

We have pioneered ways to move adhesive-backed and abrasive scrap with the least amount of moving parts. This makes Compass systems less prone to failure, downtime and costly maintenance requirements. Our automated conveyance systems use integrated control systems to reduce labor costs. Sophisticated controls also monitor and maintain process visibility in challenging environments and facilities operating 24/7. We use all major sensor brands and match them to the application to ensure both system reliability and dependable monitoring.

Our film, foil and laminate scrap recovery systems efficiently deliver scrap to any destination point, including balers, containers or directly into trucks.

Fabrication

We fabricate components for material handling systems in our Ohio factory. Here our ASME certified welders ensure that fabrication of components meets or exceeds customer requirements. Every part of a custom system is fit together and tested to ensure smooth installation and reliable performance.

Installation

Once your system is ready, we’ll be there to set it up and service it. We have supervised and built material handling facilities worldwide.

Service & Parts

We are always by your side, with global service support on all of our systems and other systems you may need support with. Call us for service support, on site audits or other needs our service department may be able to assist with.

Compass has developed All (En)Compassing solutions

For a number of film, foil and laminate related applications:

CS&S provided the pneumatic conveying systems solutions for: