Solutions

Finished Part Handling

PROBLEM: Move parts as cost-efficiently as possible without damaging them or jeopardizing the good health and safety of employees.

SOLUTION: Compass Systems mastery of Venturi-based material handling systems has been key to moving a wide variety of finished parts from bottle caps with foil inserts to delicate flashcubes. These systems move lighter weight parts using low air pressure to prevent products from banging around as they move from place to place. Generally, these type of systems are used to move parts from bulk loading to filling stations in a manufacturing process.

These type of finished parts conveyor systems also help reduce labor costs by eliminating the need for employees to fill, lift and carry heavy boxes or bags filled with parts. By automating the movement of finished parts, a number of Compass-designed systems have improved both plant safety and employee health.

Our proficiency with mechanical conveyor systems also provides an alternative way to move finished parts, especially those too heavy to move with pneumatic conveying methods. Our End-Of-Line Conveyors are specially designed to gently handle parts coming off a stamping press without marring or otherwise damaging parts. Compass Oscillating, Roller and Steel Hinged Belt Conveyors have also been used in moving heavier or boxed parts to final assembly.

OVERVIEW:

Finished Parts Handling Systems

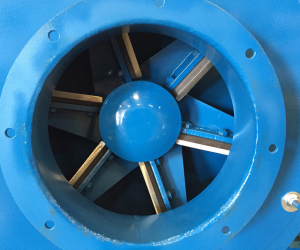

- Venturi systems move parts using low pressure, recirculated air to prevent damage from parts banging together.

- Conveyance tubing can be made out of plastic, aluminum, galvanized aluminum and other materials as the need demands.

- With both pneumatic and mechanical system experience, Compass can provide the best solution for your application.

- Automated systems eliminate the need for employees to fill, lift and carry boxes or bags of parts.

- Compass often becomes involved with systems designed to help prevent employee injuries.

- No moving parts lowers maintenance costs.

- Transported material does not come in contact with prime mover eliminating another potential source of damage to parts.

Finished Good Pneumatic Conveying System With Box Unloading

Gaylord Tipper Unit

Incline Conveyor with Oversized infeed hopper

Pressure Blower Fan With Venturi Aspirator Unit

Compass Guarantee

We will guarantee that any Finished Parts Handling System we engineer and install will perform as promised with minimum maintenance requirements. The complete Compass Systems Guarantee is available here.

System Audits

Please reach out to our technical team regarding a system audit, and potential Compass-engineered solution to ensure your material handling system is maximizing productivity and return on investment

Similar Solutions

CS&S provided the pneumatic conveying systems solutions for: