Services

Conveyor System Manufacturing

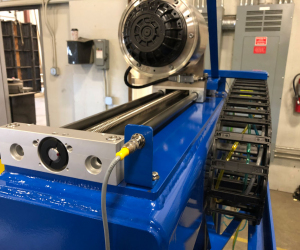

Problem: You’ve developed a custom-designed material handling system to solve a particular problem that standard equipment was incapable of solving. The components are not mass-produced. Now you have to get the system built to spec, ensuring it all fits perfectly and smoothly integrates with upstream and downstream systems and equipment. Finding a single source to reliably fabricate and warranty the entire system is difficult.

Solution: The Compass Systems manufacturing facility in Barberton, Ohio is structured to build low volume components, from conveyance tubing and mechanical conveyors to sophisticated electronic controls. It is designed to provide high-quality components, in limited quantities, to spec and to perfectly fit into custom-designed systems. To ensure perfect fit when installed, all fabrication is done to precise specs developed from comprehensive laser measurements taken at your plant. In addition, we have excellent engineering and vendor relationships with leading manufacturers of fans, vacuum producers, filters, balers and any other equipment needed for any particular system. All components are brought into our conveyor system manufacturing factory and fitted before shipping to job sites worldwide.

OVERVIEW:

Manufacturing

- 75,000 sq. ft. of manufacturing space.

- Manufacturing and engineering located in the same campus to facilitate improved integration.

- (2) 15,000 lbs capacity and (2) 10,000 lbs capacity overhead cranes.

- Advanced metal-cutting and welding capabilities.

- All systems are tested before shipping to ensure trouble-free installation.

- All components and systems fabricated are backed with the comprehensive Compass Systems Guarantee.

Compass Guarantee:

We will guarantee that any custom-designed material handling system we manufacture will perform as promised with minimum maintenance requirements. The complete Compass Systems Guarantee is available here.

CS&S provided the pneumatic conveying systems solutions for: