Solutions

Mechanical Conveyor Solutions

PROBLEM: Some scrap is so bulky or heavy it requires a mechanical means of moving from point A to point B. Often this material is being removed from the plant for recycling or being fed to shredders or balers.

There are also many situations requiring specialized handling of parts and materials of all sizes and weights. These may include free-flowing materials, boxed parts in a staging application, or finished parts coming off a stamping machine. Whether the material being moved is small or large, heavy or lightweight, a cost-efficient, low-energy method of conveyance is often required to capture, contain, move and deliver them to a destination inside or outside your plant.

SOLUTION: Compass Systems custom engineers, builds and installs different types of mechanical conveyors depending on the materials being moved and operating environments. These are low energy, small footprint answers to capturing, containing, moving and delivering scrap, finished parts and different types of materials. Compass mechanical conveyors are often the most cost-effective method of moving some materials.

OVERVIEW

Our Most Commonly Used Solutions

Although we have worked with almost every type of conveyor imaginable, there are types we use most often:

- Steel Hinged Belt Conveyors

- Oscillating Conveyors - Forward & Reversing

- Roller Conveyors

- Screw-Type Conveyors

- Rubber Belt Conveyors

- Plastic Belt Conveyors

- Bucket Conveyors

- Powered Roller Conveyors

Frequently Asked

Questions

When custom-engineering mechanical conveyor solutions, the most commonly asked questions are:

- What are you trying to convey?

- Where are you conveying it to?

- How much material is being moved?

- How much budget is available?

The answer to these questions will guide the type of conveyor used and the ultimate design of any solution we recommend. Our most common conveyor types are designed for the application in which they will be used. We have innovated ways to use mechanical conveyors to separate material grades and have developed a number of design features to make Compass conveyors easier to maintain, more durable and better suited to your needs.

- Custom-engineered solutions to integrate with systems and move different parts or materials.

- Designed for easy maintenance and long-life durability.

- Drive mechanisms are shaft mounted for longer life.

- A variety of linear solutions to capture, contain, move and deliver parts and materials.

- Different belt types and movers to suit materials and environment.

- Low energy consumption solutions.

- Small footprint solutions with motors placed below conveying surface.

- Typically these are quieter solutions to material handling needs.

- Compass guarantees the performance of the mechanical conveyors we engineer, build and install for your system.

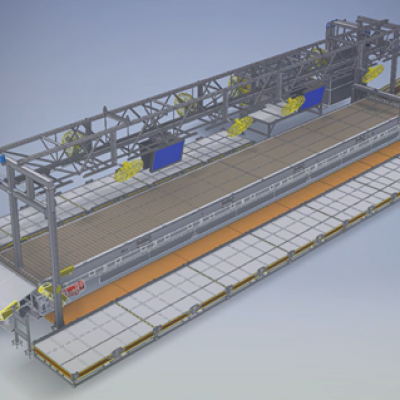

Steel Hinged Belt Conveyors

The most durable and reliable conveyors for handling heavy-duty scrap, stampings and forgings. The key design considerations are throughput, environment, material type, path and discharge point. The innovative design of Compass Steel Hinged Belt Conveyors has cut maintenance costs and extended conveyor life in a number of heavy-duty applications.

- Custom designed for the parts or material being handled.

- Surface movers, including cleats, are matched to material and volume being moved.

- Can include inclines.

- Easily scalable by adding sections and enlarging belt.

- Automatic lubrication system reduces maintenance needs.

- Easy access sub-structure simplifies maintenance.

- Elimination of wear points extends conveyor life.

- Gravity diverters can be engineered as part of the system.

- Can move forward and backward.

- 6” & 9” Pitches. 18” to 96” Widths.

- Speeds from 10 to 60 fpm.

Roller Conveyors

A series of rollers move materials forward with ease. Excellent solutions for linear movement of lighter weight materials. Roller conveyors are most often used for staging applications where boxes of material or parts are loaded and unloaded.

- Custom engineered to integrate into different material handling solutions.

- A linear solution that does not fit applications requiring elevation changes.

- Can be powered with positioning control as part of a system.

- Often used for loading and unloading applications.

Oscillating Conveyors

Tray-type design makes Oscillating Conveyors a good solution where material containment is a problem and conveyance distances are short to medium length. They are often used to move loose, granular or small materials. A mechanical crankshaft causes trays to oscillate back and forth pushing the material forward as they move.

- Custom engineered to integrate with different processes.

- Tray-shaped to contain small, loose or granular materials.

- Oscillating movement causes material to move forward.

- Short to medium travel: Approx. 5 ft. - 70 ft.

- Scalable by adding oscillating tray segments.

- Gravity diverters can be engineered as part of the system.

- Motors are placed below trays limiting footprint to the size of the conveyor.

- Not a good solution for moving materials up inclines.

Conveyor Belting

- Both 6” (15cm) pitch and 9” (23cm) pitch conveyor belting with varying widths from 18” (46cm) up through 96” (244cm) wide are available.

- The conveyor chain is sized to the application with variations in the roller diameter, bearing or bushing style friction surfaces, and end retainer construction to provide the correct chain solution for the application.

Conveyor Frames

- Both open frame and closed panel construction are available.

- Open frame construction uses structural steel members along with sheet steel to create a frame that has full access along the length of the conveyor behind expanded metal side guards.

- Closed panel construction uses sheet steel and less structural steel to create a smooth look along the conveyor with access openings at critical maintenance locations.

Slider Bed Conveyor

- Usually used in automotive stamping plants for End of Line Conveyors.

- Tubular and plate construction with various belting materials including rubber and plastic modular belting.

- Also available are indexing, extendable and varying width conveyors to suit the application.

- Drives can either be poly chain to the head shaft or a direct shaft mounted arrangement.

- Units range in width from 12” (30cm) through 96” (244cm).

- Lengths vary from 5’ (1.5m) through 200’ (61m).

Scrap Collection and Shredding Conveying System

Stamping Press Chutes

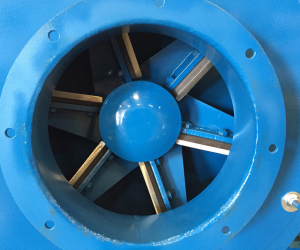

Air Knife Belt Clearing System

Automatic Belt Lubrication System

Shredder System

Pneumatic Closing Hopper

Bin and Roller Conveyor system

Single Scrap Conveyor Line

Tensioning Tail Frame

Rollout Scrap Cleanout trays

Air Knife Belting Cleanout system

‘D’ style Head Frame

Automatic Belt Hinge Lubricator

Electromagnetic and Shredder Conveyor Conversion

Electromagnet Conveyor Chute

Infeed Hopper and Sprayer with Bypass

Shredder with rollout

Material Handling Fan in Sound Enclosure

Simplified Injection Feeder Screw Conveyor

INJECTION FEEDER SCREW CONVEYOR

SCREW CONVEYOR WITH SHREDDER INFEED

INFEED METERING SCREW ASSEMBLY

Compass Guarentee:

We will guarantee that any mechanical we specify will perform in your particular application as promised with minimum maintenance. The complete Compass Systems Guarantee is available here.

System Audits:

Please reach out to our technical team regarding a system audit, and potential Compass-engineered solution, to ensure your material handling system is maximizing productivity and return on investment.

Similar Solutions

CS&S provided the pneumatic conveying systems solutions for: