Solutions

Oscillating Conveyor Systems

PROBLEM: Compass Systems custom engineers, builds and installs custom oscillating conveyors to move loose, granular or small materials short distances within your facility.

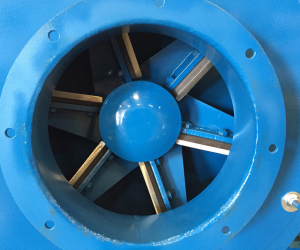

SOLUTION: Oscillating conveyor systems have a tray-type design which keep such material contained. A mechanical crankshaft causes these trays to oscillate back and forth, pushing the material forward as they move.

The oscillating motion is accomplished by specially designed inclined arms and an eccentric shaft driven by a motor through V-belts. The eccentric shaft is mounted on antifriction bearings and has V-pulleys at both ends with weights on them to counteract the unbalancing force. The rotation of the eccentric shaft provides a forward and backward motion to a connecting arm attached to the trough through a rubberized pin. The trough motion is predominantly horizontal with some vertical component, which causes it to oscillate with a pattern that moves material. A retaining spring assembly at the back of the trough absorbs shock load. All components including drive motor are mounted on a rigidly constructed base frame.

Compass systems will custom engineer your oscillating conveyor to tailor it to your unique process. Our oscillating conveyors are used to transfer hot, dry or wet abrasive metal chips, die scrap or finished parts. These conveyors can provide steady movement of material at about 12.5 feet per minute.

Different versions of the system

- Vibrating conveyor

- Oscillating conveyor

OVERVIEW:

Oscillating Type Material Handling

Plus

- Custom engineered for your process

- Tray-shaped to contain small, loose or granular materials

- Short to medium travel: 5 to 70 feet

- Scalable by adding oscillating tray segments

- Gravity diverters can be engineered as part of the system

- Motors are placed below trays limiting footprint to the size of the conveyor

- Minimize safety risks by decreasing forklift traffic

- Low maintenance

- Handles hot, wet and abrasive material

- Units can be covered and made dust tight

- Leak proof

Minus

- Not a good solution for moving materials up inclines

- Relatively short length of conveying: less than 70 feet

- Limited capacity

- Some degradation of material takes place

- Not suitable to for sticky materials like wet clay or sand

Compass Guarantee:

We will guarantee that our oscillating conveyor systems will perform as promised to improve the health, safety and cleanliness of your plant. The complete Compass Systems Guarantee is available here.

System Audits:

Please reach out to our technical team regarding a system audit, and potential Compass-engineered solution to ensure your material handling system is maximizing productivity and return on investment.

Industries & Applications

Oscillating conveyors can be used to transport toxic or chemically aggressive material through a closed trough or pipe in chemical, metallurgical and mining industries. They are also used to transport steel chips in a machine shop, hot knocked out sand, wastes and small castings in a foundry shop.

Industries making use of our oscillating conveyors include:

- Automotive

- Timber

- Waste management/recycling

- Construction materials industry

- Chemical industry

- Metallurgical industry

- Mining industry

Compass Systems is an ISO certified oscillating conveyor manufacturer with complete turnkey, custom installations. We are a global leader in pneumatic material handling and an industry innovator. Compass Systems is a full system provider with solutions for every situation. Additionally, we take quality and safety very seriously.

Compass Systems is big enough to handle large scale projects and small enough to offer the latest in technology, be reactive to customer needs and changes, and understand that every system we build is different, truly customized to fit customer needs. Our methodology allows us to maintain a competitive edge while providing innovative, safe and comprehensive solutions that increase customer productivity and profitability. Our manpower, skill, technology and determination are second to none. Together these qualities allow Compass Systems to maintain excellence in design and customer satisfaction.

Similar Solutions

CS&S provided the pneumatic conveying systems solutions for: