Solutions

Slitter & Web Dust Removal

PROBLEM: Dust from paper slitting operations creates severe product quality problems. Slitter dust is the microscopic particles that adhere to the web or escape into the atmosphere as slitting knives cut through paper. Vacuum heads placed after the slitting knives cannot remove this dust without damaging the finished product. Lower suction allows dust to remain on the web surface creating quality problems and subsequent printing problems. Higher suction deflects the web.

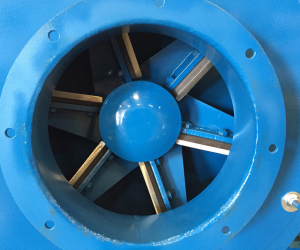

SOLUTION: Compass engineers developed a unique intake hood to capture slitter dust at the nip point. These hoods are positioned directly behind the slitter knife to vacuum up dust as it’s created. Hoods are attached to the knife guard so they move easily with the slitter knives.

Vacuum power is provided by high-performance portable vacuums or larger central vacuums for systems picking up dust from 15 or more knives. The higher CFM of these larger systems requires independent separation / filtration units ahead of the vacuum.

Vacuums are attached to a manifold in order to distribute vacuum power to the individual intake hoods. To keep the slitter & web dust removal system operating at peak efficiency each dust intake hood is connected to a manual ball valve at the manifold to shut off vacuum power to hoods not in use.

Inline Trim Chopper System

Custom Designed Edge Trim Material Intakes

Inline Trim Chopper Units on Custom Engineered Maintenance Platform

Slitter Dust Source Capture Vacuum System

Slitter Dust Intake Hoods with Manifold

Portable Vacuum Unit with Dust Collection

Kraft Paper Material and Air Separator Unit with Wet Dust Collection System

Wet Dust Collector Unit

Material and Air Separator Unit above Existing Pulper Unit

OVERVIEW:

Compass Source Capture Slitter Dust Vacuum Systems

- Captures slitter dust at the nip point.

- Prevents slitter dust from attaching to the web and causing quality problems.

- Extends knife life by smoothing knife engagement.

- Vacuum power for up to 15 knives is provided by a high-performance portable vacuum.

- Larger central vacuums are used for applications with over 15 knives.

- Manifold distributes vacuum power to individual intake hoods.

- Manual ball valves at the manifold shut off airflow to unused intake hoods.

Compass Guarantee:

We will guarantee that our Slitter Dust Vacuum Systems will perform as promised improving product quality as they capture slitter dust before it settles on the web. The complete Compass Systems Guarantee is available here.

System Audits:

Please reach out to our technical team regarding a system audit, and potential Compass-engineered solution to ensure your material handling system is maximizing productivity and return on investment

Similar Solutions

CS&S provided the pneumatic conveying systems solutions for: