Solutions

Venturi Type Material Handling

PROBLEM: Difficult to convey materials, including those with abrasive or tacky surfaces, present special material handling challenges. Other applications with high volume/mass ratios and fast-fed materials are equally challenging.

SOLUTION: Venturi-based systems are often the solution to these problems. Since Compass Systems is one of the few engineering firms extremely familiar with Venturi Systems we are uniquely positioned to help you solve a number of challenging material handling applications.

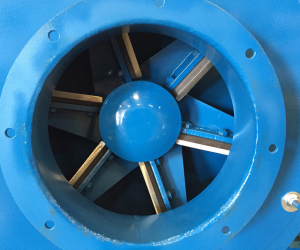

Venturi systems are named for a vacuum airflow effect first discovered by Italian physicist Giovanni Battisti Venturi in the late 1800’s. He found that when a fan draws air through a tapered pipe, or educator, the air moves at greater velocity while pressure decreases. This increased airflow makes it possible to keep up with faster feeding applications or move larger volumes of material that would overwhelm slower moving in-line fan systems. Special options, including special coatings for interior tube surfaces can be used to prevent material build-up in system components.

By removing fans from the air stream Venturi-based systems offer a number of unique benefits. Materials never come into contact with internal moving parts so long ribbons of material that would never pass through a fan can be conveyed without chopping. Abrasive and tacky materials can be handled without worrying about damage and wear to fan impellers, although conveyance tubing often requires special coatings to handle such materials. By eliminating contact between materials and moving parts, Venturi-based material handling systems are also more durable with minimum maintenance costs.

Inline Trim Chopper System

Inline Trim Chopper Units on Custom Engineered Maintenance Platform

Custom Designed Edge Trim Material Intakes

Converting Edge Trim Removal Systems

Cylcone Receiver

Granulator Unit

Eductor Unit

Air Pressure Blower Fans with Outdoor Style Air Intake Silencers

OVERVIEW:

Venturi Type Material Handling

Plus

- Provides a method of efficiently conveying abrasive and tacky materials.

- No contact between materials and internal moving parts creates clean flow-through path.

- No maintenance costs since there are no belts, bearings and other common wear items.

- System can handle long ribbons of material, eliminating the need for chopper fans. This is especially helpful when transporting non-woven materials.

- Lower noise since chopper fans are eliminated and materials do not contact impellers.

- Minimal damage to materials.

- No dust is created by system, minimizing dust mitigation concerns.

- Faster airflow makes it possible to keep up with high-speed processes.

- Capable of moving higher volumes of material than in-line fan systems.

- Options, such as special coatings, can be used to prevent material build-up at critical points.

Minus

Venturi’s are very difficult to run in sequence limiting system length to roughly 500 ft.

Higher energy consumption, especially on higher volume applications.

Requires larger discharge equipment.

Compass Guarantee:

We will guarantee that our dust collection systems will perform as promised to improve the health, safety and cleanliness of your plant. The complete Compass Systems Guarantee is available here.

System Audits:

Please reach out to our technical team regarding a system audit, and potential Compass-engineered solution to ensure your material handling system is maximizing productivity and return on investment.

Similar Solutions

CS&S provided the pneumatic conveying systems solutions for: